To guarantee straight cuts, start by accurately aligning and securing your saw blade and fence, using measurement tools like a dial indicator or square. Keep your blade sharp and properly maintained, and always prepare your workpiece by removing knots and foreign objects. Use steady, controlled pressure while guiding the material and support it evenly to prevent shifting. Regularly check your equipment for wear or misalignment—if you follow these steps, you’ll be on your way to perfect cuts every time.

Key Takeaways

- Ensure the saw blade is properly aligned parallel to the miter slot and fence for accurate cuts.

- Regularly sharpen and maintain the blade to prevent dullness and uneven cutting performance.

- Confirm the fence is securely locked and runs parallel to the blade before making cuts.

- Support workpieces adequately and use proper techniques to prevent shifting or twisting during cutting.

- Keep the table flat, level, and free of debris to ensure stability and precise alignment of the saw.

Check and Adjust Saw Blade Alignment

To guarantee your saw cuts straight and accurately, you need to check and adjust the blade alignment regularly. Start by turning off the saw and unplugging it to ensure safety. Remove any guards or covers that block access to the blade and fence. Use a combination square or dial indicator to measure the distance from the blade to the miter slot at multiple points—front and back. The blade must be perfectly parallel to the slot; any discrepancies could cause crooked cuts. Check the fence to ensure it runs parallel to the blade as well. Loosen the mounting bolts if needed and make small adjustments. Tighten everything securely once aligned. Regularly inspecting and correcting alignment keeps your cuts precise and prevents drift. Additionally, proper maintenance of your saw will help maintain consistent accuracy over time. Remember that blade alignment is essential for achieving clean, straight cuts and reducing material waste. Incorporating periodic alignment checks into your routine is a simple step to ensure ongoing precision. Performing these adjustments also helps prevent saw drift, which can compromise your project’s quality. Routine calibration can further enhance the accuracy of your cuts and extend the lifespan of your saw.

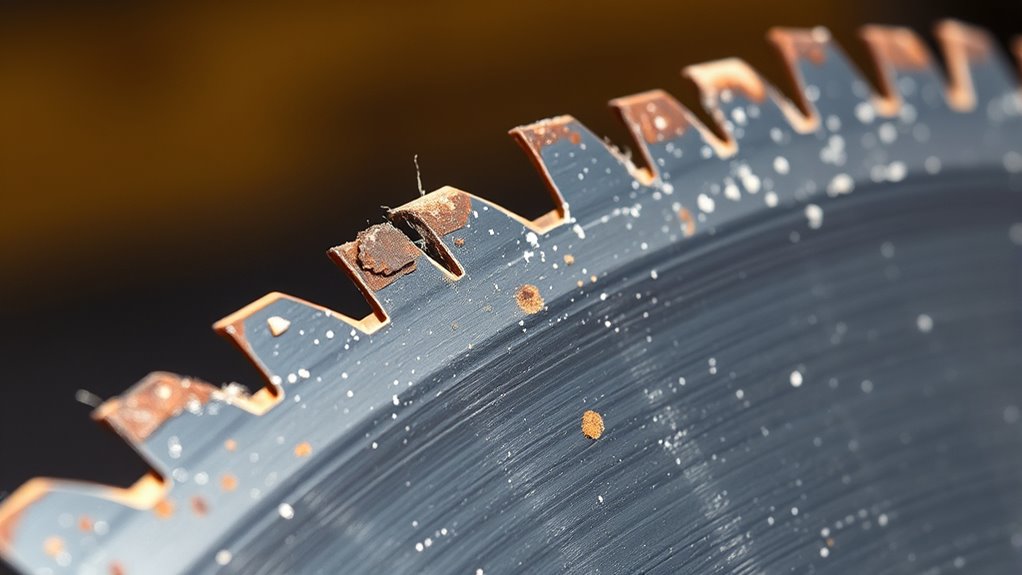

Maintain and Sharpen Your Blade Regularly

Keeping your saw blade sharp is essential for clean, accurate cuts. You should regularly inspect and sharpen it using proper techniques to prevent uneven or rough edges. Establishing a maintenance schedule guarantees your blade stays in top condition and performs reliably. Incorporating maintenance routines and energy-efficient technologies into your routine can enhance overall performance and sustainability. Additionally, using proper sharpening tools ensures your blade maintains its edge and prolongs its lifespan. Regularly checking for blade wear can help you identify when sharpening or replacement is necessary to maintain optimal cutting quality.

Significance of Sharp Blades

A sharp blade is essential for achieving clean, accurate cuts and preventing saw drift. When your blade is dull, it struggles to cut smoothly, causing your saw to veer off course and produce uneven lines. Dull blades require more force, increasing the risk of binding or kickback, which can compromise safety and precision. A well-maintained, keen blade slices through material effortlessly, ensuring straight, controlled cuts every time. Regularly inspecting your blade for dullness or damage and sharpening it when needed keeps your saw performing most effectively. Sharp blades reduce vibration, lessen stress on your equipment, and improve cut quality. Remember, a sharp, well-maintened blade isn’t just about cleaner cuts—it’s about safety, efficiency, and achieving the professional results you want.

Proper Sharpening Techniques

Regularly honing your saw blade is key to maintaining ideal cutting performance and preventing drift. Keep your blades sharp with the right tools, like a file or a sharpening stone tailored to your blade’s teeth. For crosscut blades, maintain the correct bevel angle, typically around 15-20 degrees, to ensure efficient cutting. Use consistent strokes and apply even pressure on each tooth to avoid uneven wear. Inspect the teeth frequently; dull or chipped teeth cause wandering cuts. If you’re unsure, consider professional sharpening services to restore your blade’s shape and angle precisely. Regular sharpening reduces vibration, improves cut straightness, and extends your blade’s lifespan. Make it a habit to check and sharpen before every major project for consistently clean, straight cuts. Paying attention to blade maintenance can significantly improve your saw’s performance and the quality of your cuts.

Regular Maintenance Schedule

To guarantee your saw performs at its best, establishing a consistent maintenance schedule is essential. Regularly check and clean your blade, ensuring it’s free of pitch, resin, and debris that can cause uneven cuts. Sharpen blades before they become dull to prevent wandering and crooked cuts. Also, inspect the arbor and mounting hardware to ensure everything stays secure and true. Incorporating routine inspections like checking for signs of wear and tear can extend the lifespan of your saw and improve cutting accuracy. Regular maintenance not only ensures better performance but also helps in preventing issues caused by excessive ear wax buildup that can affect equipment operation. Check fence and table alignment periodically to maintain precision.

Ensure Fence Is Properly Aligned and Secure

Make sure your fence is perfectly aligned with the saw blade to guarantee straight cuts. Check that it runs parallel to the blade using a reliable measuring tool, and tighten all securing bolts firmly. Properly securing the fence prevents shifting during cutting, giving you more accurate results. Additionally, regularly verifying the alignment with a measuring tool helps maintain consistent cuts over time. Ensuring your saw setup maintains proper thermal behavior can also prevent warping or misalignment that affects cut accuracy. Incorporating smart monitoring systems can further help detect any changes in the saw’s performance or setup, ensuring ongoing precision. Monitoring thermal stability is especially important to avoid inaccuracies caused by heat-related warping, which can be mitigated through proper tool maintenance and routine inspections.

Check Fence Parallelism

Ensuring your fence is properly aligned and secure is essential for achieving straight, accurate cuts. One key step is checking fence parallelism to the saw blade. If the fence isn’t perfectly parallel, your cuts will drift and become uneven. Use a combination square or a dial indicator to measure the distance from the fence to the blade at both the front and back. Adjust the fence until the measurements match, confirming it runs parallel. Tighten all mounting bolts securely to prevent movement during cuts. Regularly recheck this alignment, especially after moving or adjusting the fence. For the best results, consider the horsepower of electric dirt bikes to understand how motor power might influence your cutting power or tool performance. Additionally, understanding proper fence setup techniques can help maintain consistent accuracy in your cuts.

Secure Fence Properly

A secure fence is essential for accurate cuts, and it must be both properly aligned and firmly tightened. Start by checking that the fence runs parallel to the blade, using a square or dial indicator. Adjust its position if needed, ensuring there’s no wobble or looseness. Once aligned, tighten all fence bolts securely—avoid over-tightening, which can cause misalignment. Make sure the fence doesn’t shift when applying pressure to the workpiece. A loose fence leads to crooked cuts, so double-check that it stays in place during operation. Regularly inspect the fence for signs of wear or damage. Properly secured and aligned fences form the foundation for straight, precise cuts every time. Additionally, ensuring your saw’s fencing mechanisms are well-maintained can help prevent misalignments during cutting.

Inspect and Prepare Your Workpiece

Before you start cutting, it’s essential to thoroughly inspect and prepare your workpiece. Check for knots, warps, or irregular grain that could cause the blade to veer off course. Make certain the surface is flat and stable to prevent movement during cutting. Properly marking your cut line helps guide a straight cut. Additionally, you should:

- Remove any nails, screws, or foreign objects that might damage the blade or cause uneven cuts

- Support the workpiece securely to avoid shifting during sawing

- Use clamps or jigs to hold irregular or long pieces steady

Taking these steps minimizes the risk of crooked cuts and helps you achieve a clean, precise result. Proper preparation ensures your saw works efficiently and your cut stays straight.

Use Correct Cutting Techniques and Feed Pressure

Using proper cutting techniques and applying the correct feed pressure are essential for achieving straight, clean cuts. Maintain a steady, moderate pace when feeding material into the blade; rushing can cause binding or blade deflection. Push the workpiece smoothly without forcing it, letting the saw do the work. Keep your hands firm but relaxed, guiding the material steadily along the fence or miter gauge. Avoid twisting or angling the workpiece as you cut, which can drift off the line. Consistent pressure helps prevent uneven cuts caused by material shifting or blade wandering. Support the workpiece on both sides of the blade to reduce movement. By using controlled, precise technique and appropriate pressure, you’ll improve cut accuracy and avoid crooked or rough edges.

Maintain Your Equipment and Replace Worn Parts

Regularly maintaining your saw equipment and replacing worn parts is essential for consistent, accurate cuts. When you keep your tools in top shape, you reduce the risk of misalignment and uneven cuts. Regular inspections help catch issues early before they cause serious problems. Worn or damaged parts, like blades or fences, can lead to crooked or rough cuts if not replaced promptly. Proper maintenance also includes cleaning and lubrication to prevent buildup and ensure smooth operation.

- Check and tighten blade mounts and arbor nuts regularly.

- Replace dull or damaged blades immediately.

- Inspect and align fences and guides before each use.

Staying on top of maintenance not only improves cut quality but also extends your equipment’s lifespan, saving you time and money in the long run.

Optimize Blade and Tooth Selection for Your Material

Choosing the right blade and tooth configuration is vital for achieving clean, straight cuts tailored to your specific material. Select a blade with tooth geometry suited for your material type—finer teeth for plywood, coarser for hardwood. Consider the tooth count: higher for smoother cuts, lower for faster, rougher cuts. Matching blade diameter and arbor size is essential to prevent wobble. Here’s a quick guide:

| Material Type | Blade Tooth Count | Ideal Blade Type |

|---|---|---|

| Softwood | 24-40 teeth | Fine-tooth blade |

| Hardwood | 60-80 teeth | Carbide-tipped blade |

| Plywood | 80+ teeth | Thin-kerf blade |

Choosing the correct combination reduces tear-out and guarantees straight, clean cuts every time.

Confirm the Stability and Flatness of Your Saw Table

Ensuring your saw table is stable and flat is fundamental to achieving accurate, straight cuts. If the surface isn’t level, your cuts can drift or become uneven. Start by inspecting the table for any warping, dents, or debris that could cause instability. Use a straightedge or spirit level to check for flatness across the entire surface. If the table isn’t perfectly level, adjust or shim it until it is. A stable, flat surface provides consistent support for your material, reducing movement and drift during cutting.

- Regularly check for and tighten loose bolts or screws.

- Use a straightedge or level to verify flatness regularly.

- Clean the table surface to prevent material slipping or wobbling.

Calibrate Your Saw Before Starting Each Project

Before starting each project, it’s crucial to calibrate your saw to guarantee precise cuts. Begin by checking that the blade is perfectly aligned with the miter slot and fence. Use a combination square or dial indicator to measure the blade’s position at the front and back—if there’s a misalignment, adjust the blade or arbor accordingly. Confirm the fence runs parallel to the blade; slight misalignments can cause crooked cuts. Confirm the table surface is flat and free of debris that could affect accuracy. Tighten all mounting bolts and blade settings, and replace dull or damaged blades. Regular calibration helps maintain consistent precision and prevents errors from compounding during your project, ensuring every cut is straight and clean.

Frequently Asked Questions

How Does Saw Blade Wobble Affect Cut Straightness?

Saw blade wobble causes your cuts to be uneven and crooked because it creates inconsistent contact with the material. As the blade wobbles, it drifts away from the intended cut line, leading to inaccuracies. To fix this, check that the blade is securely mounted, ensure the arbor is tight, and inspect for any damage or looseness. Regular maintenance and proper blade installation help keep wobble at bay for straight, precise cuts.

Can Improper Blade Tension Cause Crooked Cuts?

Imagine the frustration of battling your saw’s imperfections—you’re right to wonder if blade tension plays a part. Yes, improper tension can subtly sway your cuts, causing them to drift crookedly. When the blade isn’t securely mounted or properly tensioned, it wobbles or deflects under pressure. This compromises precision, making your cuts uneven. Regularly check and adjust blade tension to keep your saw performing at its best, ensuring perfectly straight results every time.

What Role Does Wood Grain Play in Saw Accuracy?

Wood grain substantially impacts saw accuracy because it influences how the material responds during cutting. When you cut against the grain, the blade can catch or tear, causing crooked or rough edges. To improve accuracy, you should cut with the grain whenever possible and support the wood properly to prevent shifting. Choosing straight-grain, defect-free lumber also helps guarantee cleaner, straighter cuts and reduces deviations caused by grain irregularities.

How Does Saw Vibration Impact Cut Quality?

Vibration can turn a good cut into a shaky mess. When your saw vibrates excessively, it causes the blade to wobble, leading to uneven cuts and rough edges. To keep things steady, make sure your saw is well-maintained, blades are sharp, and the arbor is secure. Using proper technique and reducing unnecessary pressure also helps, so you don’t shake the cut to bits and get a clean, straight line.

Should I Replace the Fence if My Cuts Are Crooked?

Yes, you should replace the fence if your cuts are crooked. A misaligned or damaged fence can’t guide your material accurately, leading to uneven cuts. Check if your fence runs parallel to the saw blade; if it doesn’t, replacing or repairing it is necessary. A sturdy, properly aligned fence ensures consistent guidance, helping you achieve straight, precise cuts every time. Regularly inspect and maintain your fence for peak performance.

Conclusion

Getting a perfect cut isn’t just luck; it’s about fine-tuning your tools and technique. Think of your saw as a trusted partner that needs regular care and attention. By checking alignment, sharpening blades, and maintaining your equipment, you’re guiding your saw like a skilled conductor leading an orchestra. With patience and practice, your cuts will become as straight and smooth as a perfectly paved road—making your projects look polished and professional every time.