If you’re looking for the 14 best CNC machines of 2026, I’ve got you covered. From compact models like the Genmitsu 3018-PRO to large workhorses like the FoxAlien XE-Ultra, these machines offer high accuracy, powerful spindles, and versatile capabilities for woodworking, engraving, and even light metalwork. With features like all-metal frames, upgraded linear guides, and user-friendly software, they suit hobbyists and pros alike. Keep going to discover detailed insights on each model’s strengths and how to choose the right one.

Key Takeaways

- The list features top CNC machines with all-metal frames, high precision, and versatile work areas suitable for hobbyists and professionals.

- Machines support diverse materials including plastics, soft metals, and wood, with power ranging from 300W to 1.5kW.

- User-friendly control systems with software compatibility, WiFi connectivity, and safety features ensure ease of operation.

- Notable models like FoxAlien Masuter, NBS-6040, and Genmitsu 3018-PRO offer high accuracy, large workspaces, and upgrade options.

- Expert picks emphasize build quality, material support, software integration, and suitability for various project scales in 2026.

| FoxAlien Masuter 3S CNC Router with NEMA 23 Motor |  | Best Overall | Work Area: 15.75” x 15.75” x 3.74” | Spindle Power: 400W spindle | Control System: Dust-proof controller box, offline support | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| FoxAlien Masuter Pro 3-Axis CNC Router Machine |  | Best For Hobbyists | Work Area: 15.75” x 15.75” x 2.36” | Spindle Power: 60W/300W spindles (upgrade options) | Control System: Dust-resistant controller, easy setup | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| Carvera Air Desktop CNC Milling and Engraving Machine |  | Compact & Affordable | Work Area: 11.8” x 7.9” x 5.1” | Spindle Power: 800W trim router / upgrade to 1.5kW | Control System: All-in-one CAM software, WiFi/USB | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| FoxAlien XE-Ultra 8080 CNC Router with NEMA 23 Motor |  | Most Powerful | Work Area: 33” x 33” x 4.72” | Spindle Power: Multiple spindle options including 1.5kW VFD | Control System: Smart control box, real-time diagnostics | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

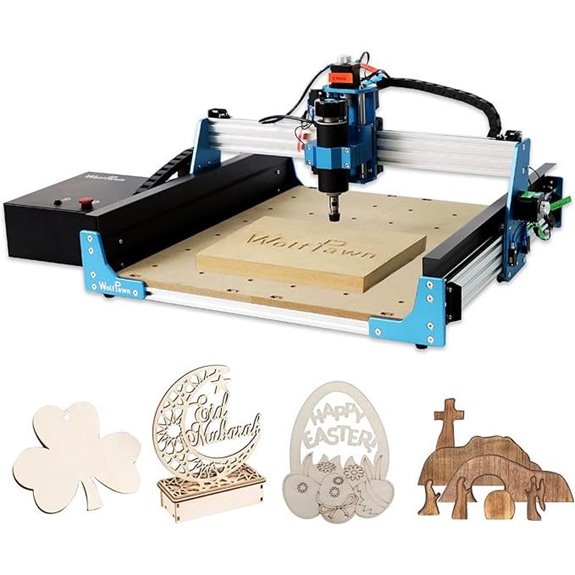

| 4040 PRO CNC Router Machine with Steel Wheel Engraver |  | Best Large Workspace | Work Area: 15.75” x 15.75” x 2.95” | Spindle Power: 500W spindle | Control System: Independent control box, compatible software | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| Genmitsu CNC 3018-PRO Router Kit with Offline Control |  | Beginner Friendly | Work Area: 11.8” x 7.1” x 4.5” | Spindle Power: 300W spindle | Control System: Open-source GRBL, PC/USB/WiFi | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| Genmitsu PROVerXL 6050 Plus CNC Router Machine |  | High Precision | Work Area: 23.62” x 19.69” x 4.53” | Spindle Power: 300W spindle | Control System: Pre-assembled, easy wiring, offline control | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

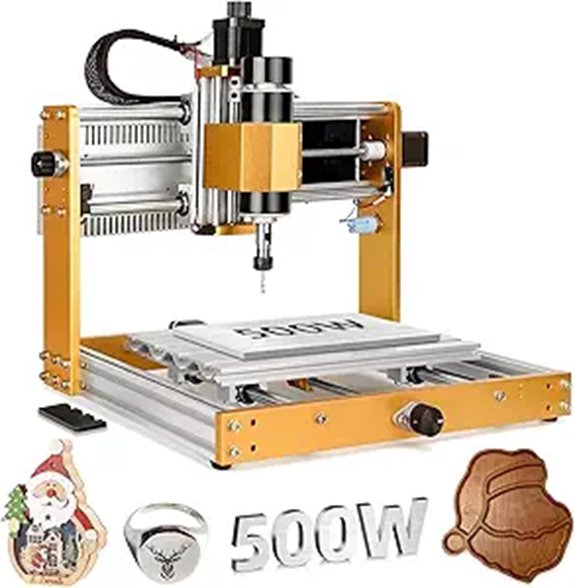

| Lunyee 3018 Pro CNC Router Machine with Limit Switches |  | Heavy-Duty Performance | Work Area: 12” x 12” x 4.7” | Spindle Power: 500W spindle | Control System: Integrated control box, limit switches | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| CNC Router 3030-Evo Max with 800W Trimmer |  | Versatile Material Support | Work Area: 24.12” x 16.21” x 4.8” | Spindle Power: 800W trim router / upgrade to 1.5kW | Control System: 32-bit control, WiFi/USB, multiple software | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

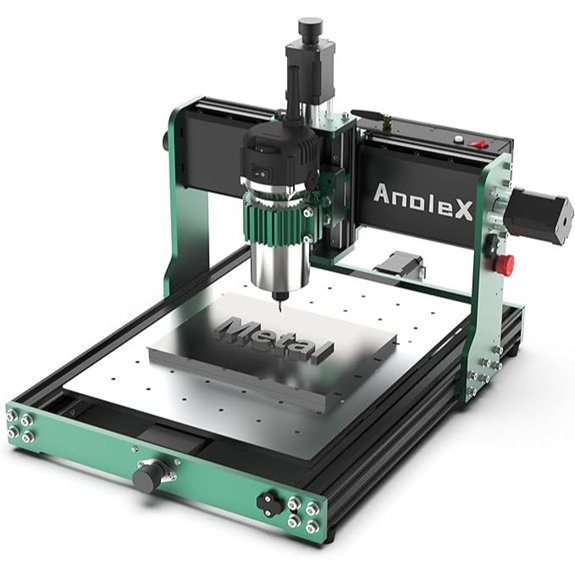

| Genmitsu CNC Router 4040-PRO for Metal & Acrylic |  | Industrial Strength | Work Area: 15.75” x 15.75” x 3.7” | Spindle Power: 300W spindle (supports 42/52mm) | Control System: Upgraded control box, multiple ports | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| LUNYEE 3018 PRO MAX CNC Router with Limit Switches |  | Deep Travel Capacity | Work Area: 12” x 12” x 4” | Spindle Power: 500W spindle | Control System: Pre-assembled, offline control, limit switches | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| NBS-6040 CNC Router with Spindle and Linear Rails |  | User-Friendly Design | Work Area: 24.12” x 16.21” x 4.8” | Spindle Power: 710W trim router / optional 1.5kW | Control System: 2.8” TFT touchscreen, offline control | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

| Genmitsu Cubiko CNC Router with Enclosure and WiFi |  | Smart & Automated | Work Area: 23.62” x 19.69” x 4.53” | Spindle Power: 800W trim router / optional 1.5kW | Control System: WiFi-enabled, app control, safety enclosure | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

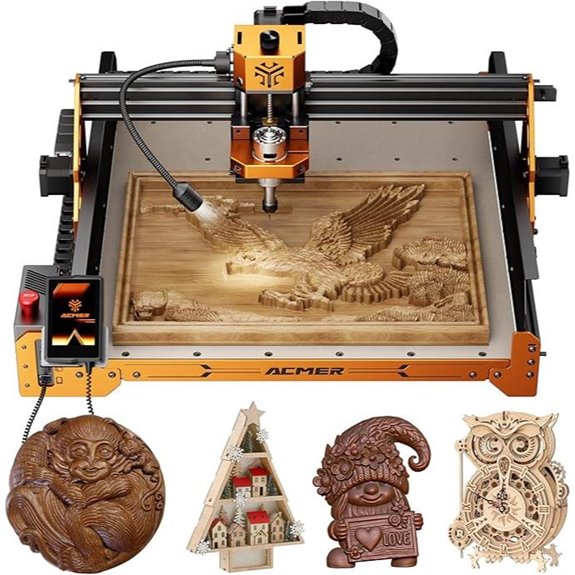

| ACMER 4S CNC Router Machine for Wood and Acrylic |  | Best For Metal & Acrylic | Work Area: 15.75” x 15.75” x 3.7” | Spindle Power: 500W spindle | Control System: Upgraded control box, multifunctional ports | VIEW LATEST PRICE | https://chatgpt.com/c/692 |

More Details on Our Top Picks

FoxAlien Masuter 3S CNC Router with NEMA 23 Motor

If you’re looking for a reliable CNC router that combines power and precision, the FoxAlien Masuter 3S with NEMA 23 motors is an excellent choice. It features NEMA23-76 closed-loop stepper motors delivering 2.2 Nm torque, with speeds up to 10,000 mm/min for efficient work. The 400W spindle handles engraving and cutting soft metals like aluminum, and an optional trimmer upgrade is available. Built with 2360mm extrusions and dual linear rails, it offers high accuracy of 0.05mm and smooth operation. Its spacious 15.75” x 15.75” x 3.74” work area, plus expandable options, make it versatile for various projects.

- Work Area:15.75” x 15.75” x 3.74”

- Spindle Power:400W spindle

- Control System:Dust-proof controller box, offline support

- Material Compatibility:Soft metals, plastics

- Build Material:Aluminum extrusions, steel components

- Upgrade Options:X-axis extension kit

- Additional Feature:Dual HG-15 linear rails

- Additional Feature:Offline control support

- Additional Feature:Optional X-axis extension kit

FoxAlien Masuter Pro 3-Axis CNC Router Machine

The FoxAlien Masuter Pro 3-Axis CNC Router Machine stands out as an ideal choice for hobbyists and DIY enthusiasts seeking a reliable and easy-to-assemble machine. Its all-metal frame with a linear rail Z-axis ensures stability, accuracy, and durability for detailed engraving on various materials like wood, acrylic, and nylon. The dust-resistant controller box with accessible emergency stop makes operation safer and more convenient. With pre-assembled components and a clear manual, setup takes just 10-15 minutes. The large working area and optional Y-axis extension allow for versatile projects, and its spindle compatibility offers room for future upgrades, making it a flexible, user-friendly CNC solution.

- Work Area:15.75” x 15.75” x 2.36”

- Spindle Power:60W/300W spindles (upgrade options)

- Control System:Dust-resistant controller, easy setup

- Material Compatibility:Wood, acrylic, soft metals

- Build Material:All-metal frame, linear rails

- Upgrade Options:Y-axis extension, custom spindles

- Additional Feature:All-metal framework

- Additional Feature:Quick assembly design

- Additional Feature:Spindle clamp options

Carvera Air Desktop CNC Milling and Engraving Machine

Designed for hobbyists, artists, and DIY enthusiasts, the Carvera Air Desktop CNC Milling and Engraving Machine stands out with its compact, fully enclosed design that prioritizes safety and cleanliness. Its small footprint, measuring just under 20 inches, fits well in limited spaces while providing a 7.9 by 5.1-inch work area. The enclosure reduces noise and contains debris, making it safer and cleaner to operate. With features like auto-probing, quick tool changes, and precise calibration, it ensures accurate results across various materials. Connectivity via WiFi or USB, combined with versatile software support, makes it an intuitive choice for creative projects.

- Work Area:11.8” x 7.9” x 5.1”

- Spindle Power:800W trim router / upgrade to 1.5kW

- Control System:All-in-one CAM software, WiFi/USB

- Material Compatibility:Wood, soft metals, plastics

- Build Material:Enclosed metal frame, steel components

- Upgrade Options:Optional 4th axis, laser support

- Additional Feature:Auto-probing & leveling

- Additional Feature:Integrated CAM software

- Additional Feature:Compact enclosed design

FoxAlien XE-Ultra 8080 CNC Router with NEMA 23 Motor

The FoxAlien XE-Ultra 8080 CNC router stands out for its impressive 33×33-inch workspace, making it an excellent choice for professionals and hobbyists tackling large projects or complex designs. Its sturdy 46×80mm aluminum frame provides excellent stability, while 16mm and 12mm ball screws on the XY and Z axes ensure precise, smooth movement. Equipped with powerful NEMA 23 stepper motors, it offers high torque and reliability at speeds up to 5,000mm/min. The machine supports various materials like wood, aluminum, and acrylic, and features safety features such as inductive limit switches and collision protection, making it versatile and dependable.

- Work Area:33” x 33” x 4.72”

- Spindle Power:Multiple spindle options including 1.5kW VFD

- Control System:Smart control box, real-time diagnostics

- Material Compatibility:Wood, aluminum, acrylic, carbon fiber

- Build Material:Aluminum frame, heavy-duty construction

- Upgrade Options:Future upgrade ports, optional 4th axis

- Additional Feature:Heavy-duty aluminum frame

- Additional Feature:Intelligent stepper motors

- Additional Feature:Future upgrade ports

4040 PRO CNC Router Machine with Steel Wheel Engraver

If you’re looking for a reliable CNC router that combines durability with precise engraving capabilities, the 4040 PRO CNC Router Machine with Steel Wheel Engraver is an excellent choice. Its sturdy all-metal frame assures stability during operation, while the sizable workspace of 15.75”x15.75”x2.95” handles various woodworking projects with ease. Powered by a robust 500W spindle, it delivers high-speed performance and accurate detail work. Most components come pre-assembled for quick setup, and it’s compatible with popular software like Lightburn and Fusion 360. Safety features, including an emergency stop button, along with extensive support, make this machine a versatile and dependable option.

- Work Area:15.75” x 15.75” x 2.95”

- Spindle Power:500W spindle

- Control System:Independent control box, compatible software

- Material Compatibility:Wood, plastic, MDF

- Build Material:Metal frame, aluminum parts

- Upgrade Options:Dust collection, offline control

- Additional Feature:Dust baffle included

- Additional Feature:Pre-assembled components

- Additional Feature:Compatible with GRBL software

Genmitsu CNC 3018-PRO Router Kit with Offline Control

For hobbyists and small-scale makers seeking reliable precision without breaking the bank, the Genmitsu CNC 3018-PRO Router Kit with Offline Control stands out as an ideal choice. It’s easy to assemble and features a raised base height for added stability, with a work area of 300 x 180 x 45mm. Capable of cutting plastics, soft aluminum, and wood, it supports a 20,000 RPM spindle without G-code modifications. The machine uses dependable open-source GRBL software and includes Carveco Maker Cam and Candle for G-code control. Its versatility, upgrade options, and solid performance make it a top pick for hobbyists wanting precision and power.

- Work Area:11.8” x 7.1” x 4.5”

- Spindle Power:300W spindle

- Control System:Open-source GRBL, PC/USB/WiFi

- Material Compatibility:Wood, plastics, soft metals

- Build Material:Aluminum profiles, steel axes

- Upgrade Options:Optional upgrades, 4th axis

- Additional Feature:Raised base height

- Additional Feature:Carveco Maker Cam software

- Additional Feature:Supports wide material range

Genmitsu PROVerXL 6050 Plus CNC Router Machine

Designed for hobbyists and small-scale professionals, the Genmitsu PROVerXL 6050 Plus CNC Router Machine offers a generous working area of 23.62” x 19.69” x 4.53” and a powerful 300W spindle motor. Its all-metal frame and dual linear rails provide stability, accuracy, and quieter operation. The hybrid table and pre-assembled core system allow for quick setup, reducing installation time. This machine handles wood, metal, acrylic, and MDF with ease, making it versatile for detailed carving projects. Its modular design, easy maintenance, and expandability options make it a reliable choice for those seeking precision and power in their CNC work.

- Work Area:23.62” x 19.69” x 4.53”

- Spindle Power:300W spindle

- Control System:Pre-assembled, easy wiring, offline control

- Material Compatibility:Metal, wood, acrylic, MDF

- Build Material:All-metal frame, aluminum extrusions

- Upgrade Options:Offline controller, dust shoe

- Additional Feature:Modular MDF spoil boards

- Additional Feature:Manual jog wheels

- Additional Feature:Hybrid table design

Lunyee 3018 Pro CNC Router Machine with Limit Switches

The Lunyee 3018 Pro CNC Router Machine with Limit Switches is an excellent choice for hobbyists and small-scale professionals seeking precise, reliable metal engraving capabilities. Its 500W all-metal spindle and upgraded Z-axis height of 80mm make metal engraving, drilling, and cutting on brass, copper, and 6061 aluminum achievable. The sturdy structure features 2040 and 4040 profiles, boosting accuracy and stability. The flat, durable aluminum work platform with a measurement scale guarantees precise positioning, while the heavy-duty T-track clamps secure workpieces firmly. Easy to assemble with clear instructions and pre-installed software, it also offers upgraded safety features like limit switches and emergency stops.

- Work Area:12” x 12” x 4.7”

- Spindle Power:500W spindle

- Control System:Integrated control box, limit switches

- Material Compatibility:Metal, wood, acrylic, PCB

- Build Material:Aluminum profiles, steel components

- Upgrade Options:Optional upgrades, dust collection

- Additional Feature:Upgraded Z-axis height

- Additional Feature:Heavy-duty linear guide

- Additional Feature:Manual handwheels included

CNC Router 3030-Evo Max with 800W Trimmer

The CNC Router 3030-Evo Max with an 800W trimmer stands out as an ideal choice for makers and small workshops seeking high precision and versatility. Its all-metal XYZ axis with dual steel linear guides ensures rigidity and accurate movement, while T8 lead screws enhance precision. The included 800W trim router with variable speeds handles metals like aluminum and copper, and can be upgraded to a 1.5kW spindle for increased power. Supported by a 32-bit control system with WiFi, it offers advanced features like laser engraving and multiple safety switches. Quick to assemble and compatible with popular software, it’s a reliable, adaptable machine for a variety of projects.

- Work Area:24.12” x 16.21” x 4.8”

- Spindle Power:800W trim router / upgrade to 1.5kW

- Control System:32-bit control, WiFi/USB, multiple software

- Material Compatibility:Metal (aluminum, copper), wood, plastics

- Build Material:Metal frame, steel linear guides

- Upgrade Options:4th axis, laser, coolant, upgradeable spindle

- Additional Feature:800W trim router included

- Additional Feature:Upgradable to 1.5kW spindle

- Additional Feature:Touchscreen control interface

Genmitsu CNC Router 4040-PRO for Metal & Acrylic

If you’re looking for a versatile CNC router capable of handling both metal and acrylic with precision, the Genmitsu CNC Router 4040-PRO stands out as an ideal choice. Its steel HSS frame offers exceptional stability, with each axis featuring dual 16 mm linear tubes, lead screw drivers, and all-metal construction. The upgraded control box includes emergency stop and home buttons, housed in a dust-proof metal casing. It supports 42mm and 52mm spindles, plus optional larger mounts, making it perfect for cutting, milling, or engraving metals and acrylics. Assembly takes about 15 minutes, and features like the 4th axis and Wi-Fi control enhance its versatility and ease of use.

- Work Area:15.75” x 15.75” x 3.7”

- Spindle Power:300W spindle (supports 42/52mm)

- Control System:Upgraded control box, multiple ports

- Material Compatibility:Metal, acrylic, wood

- Build Material:Steel HSS frame, all-metal construction

- Upgrade Options:4th axis, upgrade ports

- Additional Feature:Dual Y-axis rails

- Additional Feature:4th axis optional

- Additional Feature:Easy tool swapping

LUNYEE 3018 PRO MAX CNC Router with Limit Switches

For those seeking a durable and precise CNC router capable of handling a variety of materials, the LUNYEE 3018 PRO MAX with limit switches stands out as an excellent choice. Its all-metal construction, reinforced aluminum profiles, and 12mm optical axis guarantee stability and accuracy during operation. The machine features an 80mm Z-axis travel, the longest among standard models, allowing for deeper cuts. Equipped with a powerful 500W spindle and a speed range up to 12,000 RPM, it handles dense materials like aluminum and copper with ease. Safety is prioritized with six limit switches and an emergency stop, making it reliable and user-friendly for diverse projects.

- Work Area:12” x 12” x 4”

- Spindle Power:500W spindle

- Control System:Pre-assembled, offline control, limit switches

- Material Compatibility:Metal, wood, plastics

- Build Material:Reinforced aluminum profiles

- Upgrade Options:Optional upgrades, 12mm optical axis

- Additional Feature:Extended 80mm Z-axis

- Additional Feature:Manual positioning wheels

- Additional Feature:Offline software support

NBS-6040 CNC Router with Spindle and Linear Rails

Designed for versatility and precision, the NBS-6040 CNC Router with Spindle and Linear Rails stands out as an ideal choice for professionals and serious hobbyists alike. Its custom 710W spindle with adjustable RPM from 7,000 to 30,000 manages engraving wood, acrylic, and aluminum with ease. The machine’s linear rails and ball screws on all axes guarantee high accuracy, rigidity, and fast movement, perfect for large, demanding projects. Its open-source Grbl v1.1 control system, combined with a 2.8” touchscreen, allows seamless offline operation. The modular design supports quick setup and future upgrades, making it a flexible, powerful tool for precision manufacturing.

- Work Area:24.12” x 16.21” x 4.8”

- Spindle Power:710W trim router / optional 1.5kW

- Control System:2.8” TFT touchscreen, offline control

- Material Compatibility:Wood, acrylic, aluminum

- Build Material:Steel HSS frame, linear rails

- Upgrade Options:Expansion ports, optional accessories

- Additional Feature:710W adjustable spindle

- Additional Feature:Modular expansion ports

- Additional Feature:Offline code transfer

Genmitsu Cubiko CNC Router with Enclosure and WiFi

The Genmitsu Cubiko CNC Router with Enclosure and WiFi stands out as an ideal choice for hobbyists and small workshops seeking professional-grade results without complex setup. It’s ready to use straight out of the box—no assembly needed—letting you start carving quickly. Compatible with apps like Genmitsu, Fusion 360, Easel, and Carveco, it supports step-by-step tutorials that help beginners engrave wood, acrylic, or metal confidently. Its automatic tool height adjustment and smart surface measurement ensure precise, smooth cuts even on uneven surfaces. The safety enclosure reduces dust and noise, while WiFi and app control enable remote operation, making it versatile and user-friendly.

- Work Area:23.62” x 19.69” x 4.53”

- Spindle Power:800W trim router / optional 1.5kW

- Control System:WiFi-enabled, app control, safety enclosure

- Material Compatibility:Metal, wood, acrylic

- Build Material:Metal frame, steel components

- Upgrade Options:4th axis, laser, optional upgrades

- Additional Feature:Auto surface adjustment

- Additional Feature:Safety enclosure included

- Additional Feature:Remote WiFi control

ACMER 4S CNC Router Machine for Wood and Acrylic

If you’re looking for a highly precise and versatile CNC machine for woodworking and acrylic projects, the ACMER 4S CNC Router stands out as an excellent choice. It features a 70W spindle that’s upgradeable to 500W, reaching speeds up to 8000RPM. With a work area of 15.7” x 15.7” x 3.7”, it handles detailed engraving and carving efficiently. Its high-rigidity steel wheels on the axes guarantee durability and accuracy. The machine offers a user-friendly 3.5-inch touch screen, adjustable Z-axis, and compatibility with multiple operating systems. Designed for stability and precision, it’s perfect for DIY crafts, signage, and prototyping.

- Work Area:15.75” x 15.75” x 3.7”

- Spindle Power:500W spindle

- Control System:Upgraded control box, multifunctional ports

- Material Compatibility:Metal, acrylic, wood

- Build Material:Steel HSS frame, all-metal

- Upgrade Options:4th axis, optional accessories

- Additional Feature:Steel wheels for stability

- Additional Feature:65mm and 69mm spindles

- Additional Feature:High-precision optical axis

Factors to Consider When Choosing CNC Machines

When selecting a CNC machine, I focus on several key factors to guarantee it meets my needs. Material compatibility, work area size, and power requirements directly impact performance, while ease of assembly and software support influence setup and operation. Considering these points helps me choose the right machine for my projects.

Material Compatibility

Choosing the right CNC machine means guaranteeing it supports the materials you plan to work with, whether that’s wood, metal, acrylic, or plastics. It’s vital to check the spindle power and speed capabilities—higher wattage and RPM are needed for cutting tougher materials like aluminum or stainless steel. Make sure the machine can handle your desired material thicknesses and sizes, matching your project needs and workspace limits. Compatibility with different material densities and compositions, including soft and hard metals, composites, and delicate substrates, is essential for versatility. Additionally, consider accessory options like tool changers or specialized clamps, which can streamline working with various materials. Prioritizing material compatibility ensures top performance, reduces damage risk, and helps you achieve precise, high-quality results.

Work Area Size

Selecting the right CNC machine involves carefully considering its work area size, as this determines the maximum dimensions of the projects you can produce. A larger work area allows you to handle bigger items, but it often means a more robust, stable machine to maintain accuracy. Conversely, smaller work areas are perfect for detailed, intricate work and are usually more affordable and easier to fit into limited spaces. It is crucial to measure the dimensions—length, width, and height—to ensure the machine can handle your current and future projects. Think about potential project growth; choosing a machine with a slightly larger work area can save you from needing an upgrade later. Matching the work area size to your project scope is key to optimizing productivity and precision.

Power and Spindle

The power and spindle of a CNC machine are crucial factors that directly influence its cutting and engraving capabilities. A higher wattage spindle enables the machine to handle denser, harder materials like metals and composites more effectively. Spindle speed, measured in RPM, determines how finely the machine can cut or engrave; higher speeds yield more detailed results but require proper feed rates to avoid tool damage. Compatibility with different collet sizes, such as ER11 or ER20, expands the range of tools you can use for diverse tasks. Upgrading to a high-torque or closed-loop spindle enhances precision and stability during demanding operations. Additionally, the cooling system—air or water-cooled—affects maintenance needs and machine longevity, especially for continuous, heavy-duty work.

Ease of Assembly

When evaluating CNC machines for ease of assembly, I find that features like pre-wired components and detailed instruction manuals make a significant difference. These elements help reduce setup time and lower the learning curve, especially for beginners. Modular designs and pre-assembled main parts allow me to complete assembly in just 15 to 20 minutes, even without technical experience. Quick-connect fittings and plug-and-play features simplify the process further, reducing the need for specialized tools. Clear cable management systems and labeled components make identifying and connecting parts straightforward. Additionally, manufacturers offering extensive video tutorials and responsive customer support can make a big difference, ensuring I can troubleshoot and assemble with confidence. Overall, these features streamline setup and save valuable time.

Software Support

Choosing a CNC machine with strong software support is essential because it directly impacts how smoothly I can work on my projects. I look for machines compatible with popular software like Fusion 360, VCarve, or Mach3 to guarantee seamless design and control integration. It’s also important that the firmware, such as GRBL or LinuxCNC, works well with my preferred CAD/CAM programs to prevent conflicts. Offline operation options, like SD card or USB support, help me stay productive without internet interruptions. Regular software updates and active user communities are critical for troubleshooting and accessing new features. Finally, compatibility across multiple operating systems—Windows, Mac OS, or Linux—gives me flexibility and peace of mind, knowing I can work with the software I prefer.

Budget Considerations

Budget considerations play a pivotal role in selecting the right CNC machine, as they help me focus on options that fit my financial limits. I start by determining my overall budget range, which guides me toward suitable machines without overspending. It’s important to factor in the costs of essential accessories, upgrades, and ongoing maintenance to avoid surprises later. I also weigh the initial purchase price against long-term operational expenses like power, tooling, and repairs. Higher-priced machines often provide advanced features, better accuracy, and durability, which might justify the investment. If upfront costs are a concern, I explore financing options or leasing plans to make the purchase more manageable. Balancing upfront and long-term costs guarantees I choose a machine that offers good value and meets my production needs.

Frequently Asked Questions

What Safety Features Are Common in These CNC Machines?

The safety features I see in these CNC machines include emergency stop buttons, safety interlocks, and protective enclosures. They often have sensors to detect issues and automatically shut down if something’s wrong. Many also include dust extraction systems and thermal protections to prevent overheating. These features keep users safe while ensuring ideal machine performance, making operation safer and more reliable for everyone involved.

How Energy-Efficient Are These CNC Models?

I recently tested a new CNC model that boasts an energy efficiency of up to 30% more than older versions. These machines often feature advanced power management systems, like automatic standby modes and optimized motor controls, which markedly cut energy use. For example, in a small workshop setting, switching to such a CNC reduced electricity bills while maintaining high precision and performance. They’re designed with sustainability in mind, making them quite energy-efficient.

Can These Machines Be Upgraded for Advanced Features?

Absolutely, many of these CNC machines can be upgraded for advanced features. I’ve found that manufacturers often design them with modular components, making it easier to add new tools, software, or automation options down the line. Just keep in mind that upgrades may require compatibility checks or professional installation. I recommend consulting the manufacturer or a specialist to guarantee seamless integration and maximize your machine’s potential.

What Is the Typical Maintenance Required for These CNCS?

Maintenance keeps these CNC machines running smoothly, and neglecting it can lead to costly breakdowns. I regularly check and lubricate moving parts, clean the spindle and cooling systems, and update software. Unexpected issues can arise if you skip routine care, so I stay vigilant. Proper maintenance isn’t just routine; it’s the key to revealing consistent precision and power, giving you peace of mind and top performance every time you use your machine.

Are There Specific Software Compatibility Requirements?

Yes, there are specific software compatibility requirements I always check before purchasing a CNC machine. I guarantee the machine supports popular CAD/CAM programs like Fusion 360 or SolidWorks, and it’s compatible with Windows or Mac operating systems I use. I also verify whether the software can handle the machine’s control interface and if it supports file formats like G-code. This helps me avoid issues and keeps my workflow smooth.

Conclusion

Choosing the right CNC machine is like finding the Holy Grail—precision and power are key. Whether you’re a hobbyist or a pro, these picks cover all bases. Think of it as assembling your Excalibur; invest wisely, and you’ll carve masterpieces in no time. Don’t wait for a knight in shining armor—start today and transform your workshop into a domain of endless creativity. Your perfect CNC quest begins now!