If you’re looking for the best desk CNC machines for woodworking in 2026, I can help! I’ve found top models that offer a great balance of precision, ease of use, and versatility, from compact units like the CNCTOPBAOS CNC 3018-PRO to more advanced options like the CNC Router 4030-Evo Ultra 2. Whether you’re a hobbyist or small workshop, these picks are worth considering. Keep going to learn more about each machine’s capabilities and what makes them stand out.

Key Takeaways

- The best desk CNC machines in 2026 offer a range of sizes from compact to large, suitable for hobbyists and professional woodworking.

- Key features include high precision (±0.05mm or better), easy assembly, and versatile software compatibility.

- Many models incorporate all-metal construction, upgraded guides, and dust-proof features for durability and maintenance ease.

- User-friendly options like plug-and-play setups and automatic adjustments make CNC woodworking accessible for beginners and experts.

- Advanced options support multiple materials such as wood, acrylic, and soft metals, with customizable upgrade potential.

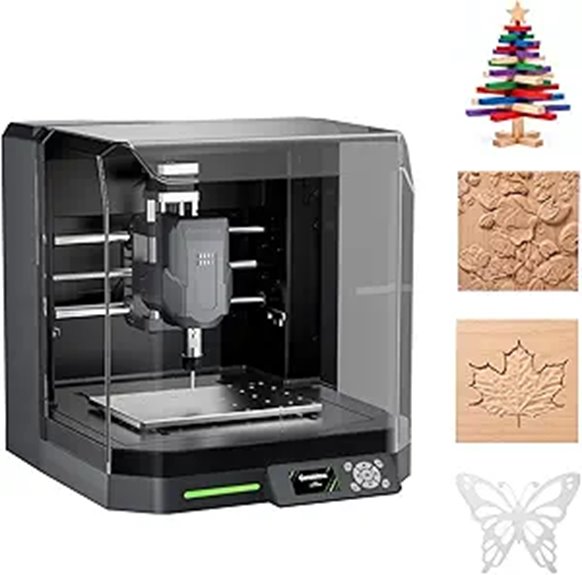

Genmitsu Cubiko CNC Router with Enclosure and WiFi

If you’re new to CNC woodworking or want a hassle-free setup, the Genmitsu Cubiko CNC Router with Enclosure and WiFi is an excellent choice. It’s ready to use straight out of the box—no assembly needed—so you can start carving quickly. It supports popular apps like the Genmitsu App, Fusion 360, Easel, Candle, and Carveco, making it versatile and easy to operate. Beginners will appreciate the step-by-step tutorials for engraving wood, acrylic, and even metal. Its automatic tool height adjustment and smart surface measurement guarantee precise, smooth results on uneven surfaces. Plus, the safety enclosure keeps debris contained and halts operations if opened, prioritizing safety.

Best For: hobbyists, beginners, and small workshop users seeking a ready-to-use, versatile CNC router with safety features and WiFi connectivity.

Pros:

- No assembly required; plug and play design for quick setup.

- Supports multiple popular CAD/CAM applications like Fusion 360 and Easel, enhancing versatility.

- Automatic tool height adjustment and surface measurement ensure precise carving on uneven surfaces.

Cons:

- May be limited for large-scale industrial projects due to its desktop size.

- Metal cutting capable but with a maximum depth of 0.5mm per pass, requiring multiple passes for thicker cuts.

- The safety enclosure, while beneficial, may restrict access during complex operations or troubleshooting.

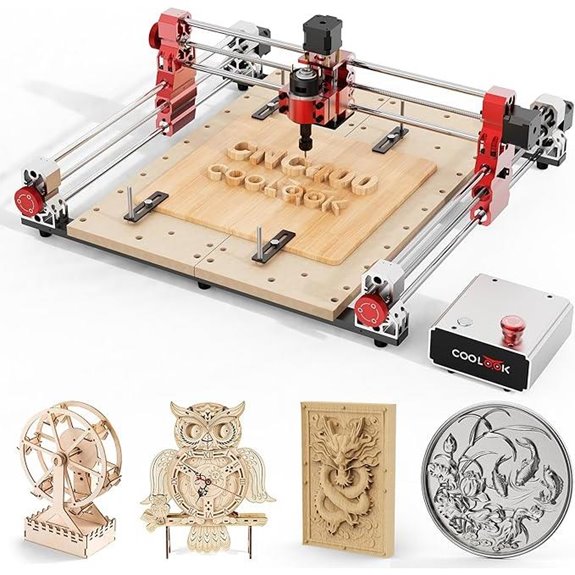

CNC400 Desktop Woodworking Engraver & Router Machine

The CNC400 Desktop Woodworking Engraver & Router Machine is an excellent choice for enthusiasts and professionals who need precise, large-area engraving capabilities. It features a spacious 400mm x 400mm x 80mm work area, perfect for complex designs and bigger projects. With an engraving accuracy of ±0.05mm, a maximum speed of 500mm/min, and a sturdy aluminum frame, it ensures stable, detailed results. The machine supports various materials like wood, acrylic, and carbon fiber, with a spindle reaching 8000RPM. Its user-friendly interface reads G-code via USB or TF card, making setup and operation simple for creators of all levels.

Best For: hobbyists, educators, and professionals seeking precise, large-area woodworking and engraving capabilities for complex or sizable projects.

Pros:

- Large working area of 400mm x 400mm x 80mm allows for versatile and larger designs

- High engraving accuracy of ±0.05mm ensures detailed and precise results

- Supports multiple materials like wood, acrylic, and carbon fiber with a stable aluminum frame

Cons:

- Maximum speed of 500mm/min may be slow for high-volume production

- Requires familiarity with G-code or software setup, which might be challenging for beginners

- Limited to materials that are biodegradable or compatible with the machine’s specifications

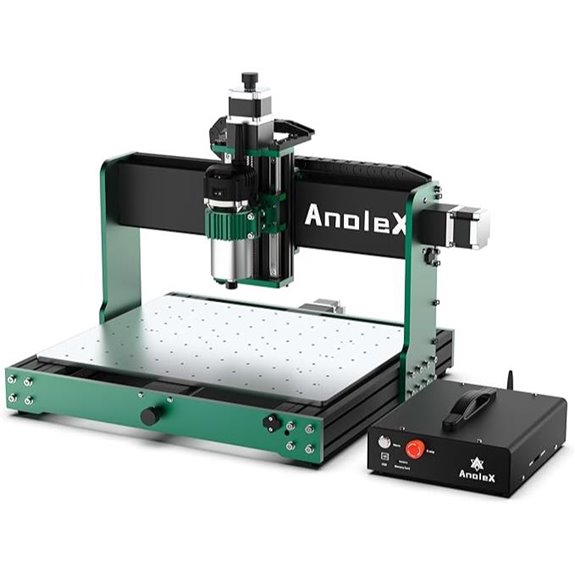

CNC Router 4030-Evo Ultra 2 with 800W Router

Designed for serious hobbyists and small workshop owners, the CNC Router 4030-Evo Ultra 2 with an 800W router packs impressive precision and versatility into a compact, all-metal frame. Its XYZ axes feature dual steel linear guides and 1204 ball screws, ensuring accuracy and rigidity. The machine supports various materials, including wood, aluminum, and acrylic, thanks to its powerful 800W trim router with adjustable speeds up to 24,000 RPM. Connectivity is seamless with WiFi, PC, or tablet control, and compatibility spans Windows, Linux, and Mac. Easy assembly, reprogrammable functions, and upgrade options make it a versatile choice for both beginners and experienced users.

Best For: serious hobbyists and small workshop owners seeking a versatile, precise, and easy-to-upgrade CNC router for working with wood, aluminum, and acrylic.

Pros:

- All-metal XYZ axes with dual steel linear guides and ball screws for enhanced accuracy and rigidity

- Seamless connectivity via WiFi, PC, or tablet with broad software compatibility including GRBL, Fusion 360, and Lightburn

- Compact design with easy assembly, reprogrammable functions, and upgrade options for future enhancements

Cons:

- Limited to 83.6 pounds, which may require effort to move or reposition

- No batteries included, requiring an external power source and corded connection

- First availability scheduled for January 13, 2025, potentially delaying initial purchase or setup

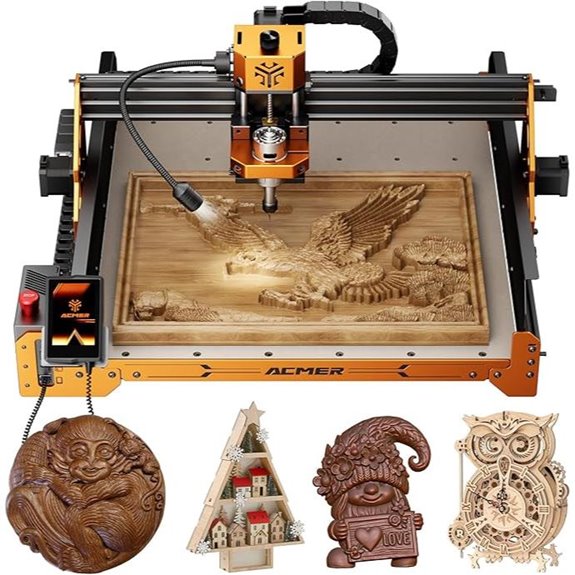

ACMER 4S CNC Router Machine for Wood and Plastic

The ACMER 4S CNC Router Machine stands out for its impressive 70W spindle power, which is upgradeable to 500W, making it ideal for woodworking and plastic engraving enthusiasts seeking high precision. It delivers ±0.1mm accuracy on materials like wood, acrylic, and epoxy, with a maximum carving speed of 1,000mm/min. Its sturdy high-rigidity frame, upgraded steel wheels, and protective covers ensure durability and stability during heavy-duty tasks. The user-friendly 3.5-inch touch screen and organized cable management make operation straightforward. Plus, its modular design simplifies assembly and repairs, while compatibility with multiple software platforms adds versatility for various projects.

Best For: hobbyists, small workshop owners, and DIY enthusiasts seeking high-precision CNC routing for wood and plastic projects with easy setup and reliable performance.

Pros:

- Upgrades from 70W to 500W spindle power for versatile high-precision carving

- Durable high-rigidity frame with upgraded steel wheels ensures stability and long lifespan

- User-friendly 3.5-inch touch screen and modular design simplify operation, assembly, and maintenance

Cons:

- Maximum carving speed of 1,000mm/min may be limiting for very large or fast-paced production tasks

- Requires a compatible software platform and some initial setup knowledge for optimal use

- Limited to materials like wood, acrylic, epoxy, and tooling boards; not suitable for metals

Carvera Air Desktop CNC Milling Machine

If you’re looking for a compact CNC machine that delivers professional precision in a small footprint, the Carvera Air Desktop CNC Milling Machine is an excellent choice. Its 11.8 x 7.9 x 5.1-inch work area is perfect for detailed carving, engraving, and milling projects. The fully enclosed design keeps noise and debris contained, making it suitable for various workspaces. With high-precision components like a spindle runout below 0.01mm and motor resolution of 0.005mm, it ensures accuracy. Plus, auto-probing, quick tool changes, and versatile software support make it ideal for hobbyists and artists seeking reliable, precise results.

Best For: hobbyists, artists, and DIY enthusiasts seeking a compact, precise, and versatile desktop CNC machine for creative projects.

Pros:

- Compact size with a large work area suitable for detailed work

- High-precision components ensuring professional accuracy

- Enclosed design reduces noise and debris, maintaining a clean workspace

Cons:

- Limited to small to medium-sized projects due to its work area

- May require some technical setup for beginners unfamiliar with CNC operation

- Optional upgrades like 4th axis or laser may involve additional cost and complexity

Genmitsu 3020-PRO MAX V2 CNC Router with Offline Control

For woodworkers seeking precision and ease of use, the Genmitsu 3020-PRO MAX V2 CNC Router with Offline Control stands out as an excellent choice. It features an 11.8 x 8.1 x 3.1-inch working area and upgraded 3-axis capabilities for cutting wood, metal, acrylic, and more. The sturdy frame, including a reinforced Y-axis profile and dual steel X-axis guide rails, guarantees stability and accuracy. Setup is straightforward with pre-assembled modules and organized wiring. The machine runs on open-source Grbl V1.1, with upgraded Toshiba drivers and an offline controller, making operation hassle-free for both beginners and experienced users.

Best For: woodworkers and hobbyists seeking a stable, precise CNC router for small to medium-sized projects with easy setup and reliable operation.

Pros:

- Robust construction with upgraded Y-axis profile and dual steel X-axis guide rails for enhanced stability and accuracy

- Pre-assembled modules and organized wiring for quick and straightforward setup

- Upgraded offline controller and open-source Grbl V1.1 compatibility for versatile and hassle-free operation

Cons:

- Limited working area of 11.8 x 8.1 x 3.1 inches may not accommodate larger projects

- May require some technical knowledge for optimal setup and maintenance

- Additional accessories or upgrades might be needed for advanced applications or material-specific machining

SainSmart Genmitsu 4040 PRO CNC Milling Machine

Designed for precision and versatility, the SainSmart Genmitsu 4040 PRO CNC Milling Machine stands out with its support for a 4-axis rotation kit, enabling multi-angle carving and 3D rotary work. It’s compatible with GRBL v1.1 control and can integrate wireless modules for easier operation. Built with high-rigidity steel HSS linear tubes, dual Y-axis rails, and a full metal frame, it offers excellent stability for detailed milling. The machine is quick to assemble, with pre-assembled parts, and features modular upgrades like different spindle sizes. Whether working with wood, metal, or acrylic, it’s a robust choice for precise, heavy-duty projects.

Best For: hobbyists, educators, and small-scale professionals seeking a versatile, high-precision CNC milling machine for woodworking, metal, or acrylic projects.

Pros:

- Supports 4-axis rotation for multi-angle carving and 3D rotary work, expanding creative possibilities

- Constructed with high-rigidity steel HSS linear tubes and full metal frame for enhanced stability and accuracy

- Quick to assemble with pre-assembled parts and modular upgrade options, saving setup time and allowing customization

Cons:

- May require technical knowledge for optimal setup and integration of wireless modules and upgrades

- Limited spindle size options may restrict some heavy-duty applications without additional modifications

- As a desktop machine, it might not handle very large or industrial-scale projects

SainSmart Genmitsu 3020-PRO CNC Router with Upgraded Spindle

The SainSmart Genmitsu 3020-PRO CNC Router with Upgraded Spindle stands out as an excellent choice for hobbyists and small-scale woodworkers who need precise, versatile, and reliable machining. Its all-metal construction and compact size make it stable and easy to set up. The powerful 710W spindle can handle materials like wood, aluminum, acrylic, and even soft titanium, with adjustable speeds up to 30,000 RPM. Dual steel X-axis guides and reinforced components ensure accuracy during demanding cuts. Designed for quick installation and user-friendly operation, this CNC router delivers professional results in a compact, reliable package perfect for creative projects.

Best For: hobbyists, small-scale woodworkers, and creative enthusiasts seeking precise, versatile, and reliable CNC machining.

Pros:

- All-metal construction provides durability and stability during demanding cuts

- Powerful 710W spindle with adjustable speeds up to 30,000 RPM handles a variety of materials including wood, aluminum, and soft titanium

- Quick setup and user-friendly design make it accessible for both beginners and experienced users

Cons:

- Limited work area of 11.8″ x 8.1″ x 3.1″ may not accommodate larger projects

- Compatibility with additional laser modules or brackets may require separate purchase of optional accessories

- The compact size, while ideal for small projects, may restrict scalability for larger or more complex machining tasks

Genmitsu PROVerXL 4030 V2 CNC Router (400x300x110mm)

If you’re looking for a versatile and precise CNC router that can handle small to medium-sized projects, the Genmitsu PROVerXL 4030 V2 stands out. It’s designed for fast, accurate cutting and engraving on wood, metal, acrylic, PCB, and MDF within a 400x300x110mm workspace. Its closed-loop motor reduces step loss and noise, reaching speeds up to 5000 mm/min, which boosts productivity. The upgraded motion system with 1204 ball screws and a sturdy Z-axis guarantees high accuracy. Easy to operate via USB with GRBL control and compatible software, it’s perfect for hobbyists, DIYers, and small-scale production.

Best For: hobbyists, DIY enthusiasts, and small businesses seeking a versatile, precise CNC router for small to medium-sized projects.

Pros:

- High accuracy and precision thanks to upgraded motion system with 1204 ball screws and a sturdy Z-axis.

- Fast operation with a maximum speed of 5000 mm/min, improving productivity.

- Easy to use with USB connectivity and compatible GRBL-based software like Candle or Universal Gcode Sender.

Cons:

- Limited working area of 400 x 300 x 110 mm may not suit larger projects.

- Requires some technical knowledge for setup and calibration.

- May need additional accessories or upgrades for advanced materials or complex designs.

LUNYEE 4040 PRO CNC Router with 3-Axis Metal

For hobbyists and small workshops seeking a versatile, beginner-friendly CNC router, the LUNYEE 4040 PRO stands out with its all-metal 3-axis design and quick setup. It offers a 15.75” x 15.75” x 3.1” workspace, suitable for engraving wood, metal, and acrylic. Built with a reinforced aluminum gantry, dual linear guides, and a 1204 ball screw Z-axis, it ensures stability and precision. Its dust-proof features include magnetic covers and sealed belts, reducing maintenance. With pre-assembled modules and simple wiring, it’s ready in about 15 minutes. Its compatibility with various spindles and upgrade options makes it a flexible choice for both beginners and small-scale projects.

Best For: hobbyists and small workshops seeking an easy-to-setup, versatile CNC router for engraving and cutting various materials.

Pros:

- Quick, beginner-friendly setup with pre-assembled modules and simple wiring.

- All-metal design with dust-proof features for enhanced durability and low maintenance.

- Supports multiple spindles and upgrade options for versatile applications.

Cons:

- Limited working area of 15.75” x 15.75” x 3.1”, which may not suit larger projects.

- Weighs approximately 38.9 pounds, potentially challenging for frequent relocation.

- Basic control features may require familiarity with GRBL software for optimal operation.

CNC Vise for Desktop Router, 7.87″x3.94

A CNC vise measuring 7.87″ x 3.94″ is an ideal choice for hobbyists and professionals using desktop routers like the LUNYEE 3018 and 4040 series. Its high-precision aluminum construction provides a stable platform for accurate engraving, cutting, and machining. With a maximum clamping range of 136mm, it securely holds workpieces of various sizes, boosting stability during operations. The vise’s two 60mm long mounting slots make installation on most workbenches simple and secure. Overall, this versatile worktable enhances precision and durability, making it a valuable accessory for woodworking, metalworking, and detailed projects on desktop CNC machines.

Best For: hobbyists and professionals using desktop CNC routers like the LUNYEE 3018 and 4040 series seeking a stable, precise, and durable workholding solution.

Pros:

- High-precision aluminum construction ensures stability and accuracy during machining.

- Versatile clamping capacity of up to 136mm accommodates various workpiece sizes.

- Easy to install with two 60mm long mounting slots compatible with most workbenches.

Cons:

- Designed specifically for LUNYEE 3018 and 4040 series, limiting compatibility with other CNC models.

- May require additional accessories for optimal use on certain workbenches.

- Slightly limited work surface size for larger projects.

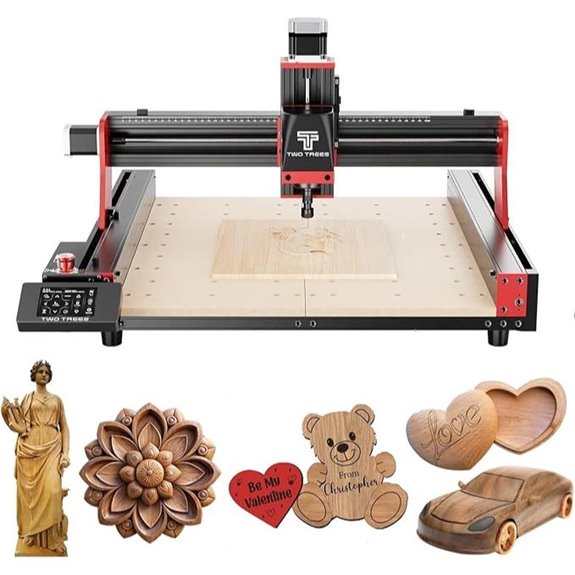

Twotrees TTC450 Pro CNC Router with Touch Screen

The Twotrees TTC450 Pro CNC Router with Touch Screen stands out for its exceptional precision, making it ideal for hobbyists and professionals who demand detailed, high-quality engravings. It offers an impressive 0.01mm X/Y and 0.0025mm Z-axis accuracy, ensuring smooth, accurate results. Its 460×460×80mm workspace handles wood signs, model parts, and metal engravings comfortably. Powered by a standard 775 spindle motor, upgradeable to 3000W, it supports various materials like plywood, acrylic, and aluminum. The intuitive 3.5-inch full-color touchscreen, combined with GRBL firmware and multiple connectivity options, makes operation seamless and versatile for a wide range of projects.

Best For: hobbyists, makers, and professionals seeking high-precision CNC engraving with versatile material support and an intuitive touchscreen interface.

Pros:

- Extremely high accuracy of 0.01mm X/Y and 0.0025mm Z-axis positioning ensures detailed results.

- Large 460×460×80mm workspace accommodates a variety of projects including wood, metal, and acrylic.

- User-friendly 3.5-inch full-color touchscreen coupled with multiple connectivity options for easy operation.

Cons:

- Requires upgrades if more powerful spindle motor is needed beyond the standard 775 model.

- Limited to 800mm/min maximum carving speed, which may be slow for high-volume production.

- The need for compatible software setup and calibration might be challenging for complete beginners.

CNCTOPBAOS CNC 3018-PRO Wood Router Kit

If you’re just starting in woodworking or CNC engraving, the CNCTOPBAOS CNC 3018-PRO Wood Router Kit stands out for its compact size and user-friendly design. Its small frame (420x350x270mm) offers a working area of 300x180x45mm, perfect for hobby projects. Made with a durable resin frame and aluminum workbench, it’s lightweight yet sturdy. Equipped with a powerful 775 spindle motor and Nema17 stepper motors, it ensures precise, efficient cuts. The upgraded GRBL control system supports a variety of materials like wood, plastic, and soft metals. Overall, it’s an excellent choice for beginners seeking a versatile, easy-to-operate CNC machine.

Best For: hobbyists and beginners seeking an affordable, compact CNC machine for precision engraving and carving on wood, plastic, and soft metals.

Pros:

- Compact and lightweight design ideal for small workshops and hobby projects

- Easy to operate with upgraded GRBL control system and user-friendly software

- Versatile material compatibility including wood, plastic, acrylic, and soft metals

Cons:

- Limited working area may not suit large-scale projects

- No included automatic tool changer or advanced automation features

- Requires some technical setup and calibration, which may be challenging for absolute beginners

Factors to Consider When Choosing a Deskcnc Machine for Woodworking

When choosing a desk CNC machine for woodworking, I consider factors like material compatibility, precision, and size to match my projects. I also look at how easy the software is to use, along with my budget and potential upgrades. These points help guarantee I pick a machine that fits my needs and setup perfectly.

Material Compatibility

Choosing a CNC machine for woodworking means guaranteeing it can handle the specific materials you plan to work with. I always check if the machine supports cutting and engraving on my preferred wood types, whether hardwood, softwood, or plywood. It’s also vital to verify that it can handle the maximum thickness I might use, which can range from a few millimeters to several centimeters. I pay attention to spindle power and speed to guarantee precise carving of detailed designs or larger profiles. Compatibility with software that generates optimized toolpaths is essential for efficient processing. If I work with other materials like acrylic or MDF, I make sure the machine can handle those as well. Proper material compatibility guarantees smooth operation and high-quality results in my projects.

Cutting Precision and Speed

Achieving high cutting precision and speed is essential for efficient woodworking with a CNC machine. Higher spindle speeds, like 24,000 RPM, enable faster cuts and more detailed engraving, saving time and enhancing finish quality. Precision levels of ±0.05mm or better guarantee accurate cuts and fine details in complex projects. Faster travel speeds, such as 5000 mm/min, make operations quicker without sacrificing accuracy. Ball screw mechanisms on axes improve stability and reduce backlash, which boosts precision at high speeds. Automated tool height adjustment and surface measurement features help maintain consistent accuracy during complex cuts. When selecting a machine, look for these specs to balance speed and precision—key to achieving professional results efficiently.

Machine Size and Space

Selecting the right desk CNC machine requires careful consideration of its size and how it fits into your workspace. You need to verify the machine’s dimensions comfortably fit, leaving enough clearance for ventilation and easy access. The maximum working area should match the size of your typical projects and materials, so you don’t outgrow your machine too quickly. Check the height and footprint to see if it integrates smoothly with your existing workbench or station setup. Don’t forget to leave extra space for tool changes, material loading, and maintenance access. Also, consider if the machine allows proper dust collection, cooling, and safety features without crowding your workspace. Proper sizing makes operation safer, more efficient, and leaves room to grow.

Software and Control Ease

When evaluating desk CNC machines for woodworking, the ease of software and control systems can make a significant difference in your workflow. I look for user-friendly interfaces like GRBL, Mach3, or proprietary programs that simplify operation and reduce setup time. Intuitive controls such as touchscreens, manual jog wheels, or offline controllers are game-changers, making maneuvering straightforward. Compatibility with my computer’s operating system—whether Windows, macOS, or Linux—is essential to avoid integration headaches. I also prefer machines that come with pre-installed software or easy-to-install drivers, so I can start working quickly. Features like real-time monitoring, auto-calibration, and customizable macros enhance usability and precision, ensuring I can focus on my projects without fussing over technical details.

Budget and Upgrades

Budget is a crucial factor when choosing a desk CNC machine for woodworking, as it determines which features and models are within reach. You should consider the initial cost and whether it fits your budget constraints, balancing price with desired capabilities. Think about future upgrades like spindle power, bed size, or additional axes—it’s smart to evaluate their availability and costs upfront. Check if the machine supports upgradeable components or modular attachments, allowing you to expand functionality over time without replacing the entire unit. Comparing entry-level models to those with advanced features can help you decide if investing a bit more now could reduce future upgrade expenses. Ultimately, verify that any upgrade options are compatible with your current setup to avoid unexpected compatibility costs.

Frequently Asked Questions

What Safety Features Are Included in Modern Desktop CNC Machines?

Modern desktop CNC machines include several safety features I find essential. They often have emergency stop buttons, so I can quickly halt operations if needed. Many also come with enclosure shields to contain debris and reduce noise, plus auto shut-off systems that activate when sensors detect issues. Additionally, safety interlocks prevent accidental start-ups when covers are open, giving me peace of mind during my woodworking projects.

How Easy Is It to Upgrade or Customize These CNC Machines?

Did you know over 75% of desktop CNC users customize their machines? Upgrading and customizing these CNC machines is quite straightforward. I find that most models feature modular parts and open-source software, making it easy to add new tools or improve performance. Whether you want to upgrade the spindle or tweak the firmware, these machines are designed with hobbyists and professionals in mind, so flexibility is built right in.

What Are the Typical Maintenance Requirements for These Machines?

Maintaining these CNC machines is pretty straightforward. I check and tighten belts and screws regularly to keep everything aligned. I also clean the dust and debris after each use to prevent buildup, which can affect precision. Lubricating moving parts monthly helps reduce wear and tear. Additionally, I run software updates and calibrate the machine periodically to guarantee peak performance. Overall, consistent small efforts keep my machine running smoothly.

Can These CNC Machines Handle Materials Other Than Wood and Plastic?

Imagine these CNC machines as versatile chefs in a busy kitchen; they can handle more than just wood and plastic. I’ve seen them work on soft metals like aluminum and even foam, carving intricate designs with ease. While they excel at many materials, I always check the machine’s specifications first. With proper tools and settings, these machines can definitely serve up creative projects across various materials.

What Is the Average Learning Curve for Beginners Using These Machines?

The learning curve for beginners using these CNC machines typically takes around 10 to 20 hours of practice. At first, I found it a bit challenging to master the software and settings, but with patience and regular use, I became more confident. Most machines come with tutorials and community support, which really helped me get comfortable quickly. Overall, I’d say it’s manageable if you’re willing to learn and experiment.

Conclusion

No matter which desktop CNC machine you pick, remember that the right tool can make all the difference. It’s worth doing your homework so you don’t end up biting off more than you can chew. With the top picks on this list, you’ll be well on your way to turning your woodworking dreams into reality. So go ahead, take the plunge—sometimes, you’ve gotta jump in with both feet!